Swebor abrasion resistant steel

Fighting abrasion wear of steel plate

1. Introduction

One of the high-quality products manufactured in our company is SWEBOR ABRASION RESISTANT STEEL, intended for uses in which severe wear due to abrasion occurs. But, what is abrasive wear and how can it be counteracted? To answer these questions, we have prepared this publication, the purpose of which is to explain the abrasive wear process in components made of steel plate and to give users some guidelines to minimize its damaging effect. Our hope is also that it will help the user make a better selection of materials for components used in situations where abrasive wear must be reduced.

By using the right material, the user will have significant benefits such as increasing the useful life of the component or reducing its weight, which gives you further advantages. SWEBOR ABRASION RESISTANT STEEL is also ‘production-friendly’ and of homogeneous properties, which is backed by our delivery security and our technical service.

SWEBOR ABRASION RESISTANT STEEL is already being used in applications where it is exposed to abrasive wear, and the number of wear-resistant qualities we produce is constantly increasing. Customers will discover how best to use these steels, and find new applications for them. They will also find that costs can be significantly reduced and that the useful life of parts made from these steels is much longer.

This booklet is based on the author’s decades of knowledge and experience in the field of Wear of Metals, especially in abrasion resistant steels. Several scientific and educational publications written by the author have served as a base for this booklet, which is easily digestible even for the non-technical reader. Therefore, no other references are mentioned.

Copyright © José Rendón and Swebor.

2. Wear of metals in general

Wear takes place all the time and in all places—for better or for worse. So is the case of all machinery. It can sometimes be desirable, such as when a material is machined or sandblasted, but in general the goal of a builder and the users is to counteract wear and extend the useful life of their machines.

By definition, wear is a phenomenon where material is removed from the contact zone between two bodies that come into dynamic contact with each other. This removal of material takes place in different ways, depending on the prevailing circumstances. Take, for example, wear on ball bearings and wear on the flatbed of a truck used for transporting stones, gravel or sand. In the first case the contact takes place between two metals, while in the second case the flatbed comes in contact with pieces of stone. In addition, the bearings are lubricated, which is not the case with a truck bed.

2.1. Wear mechanisms

Wear research has shown that four basic mechanisms account for most of the wear of materials in general, including steels. These mechanisms are the following: abrasion, adhesion, surface fatigue and tribochemical (oxidation-corrosion) mechanisms.

2.1.1. Abrasive mechanism

This mechanism takes place when a hard body, particle or surface irregularity penetrates the surface of a softer material, slides over it or strikes it. Then chips from the worn material break away or scratches are formed in the worn material. We will treat this issue in more detail later on, because it is normally related to wear of steel plate.

2.1.2. Adhesive mechanism

More common among metals, this mechanism occurs when irregularities on the surface of two metals come into contact with each other. During the contact process, a limited number of microscopic contact points will merge together. During successive movement, these contact points will break, not at the point of contact, but in an area where the material is weaker. This results in the loss of material in the softer body. This type of mechanism occurs mainly in the absence of lubrication or in poor lubrication.

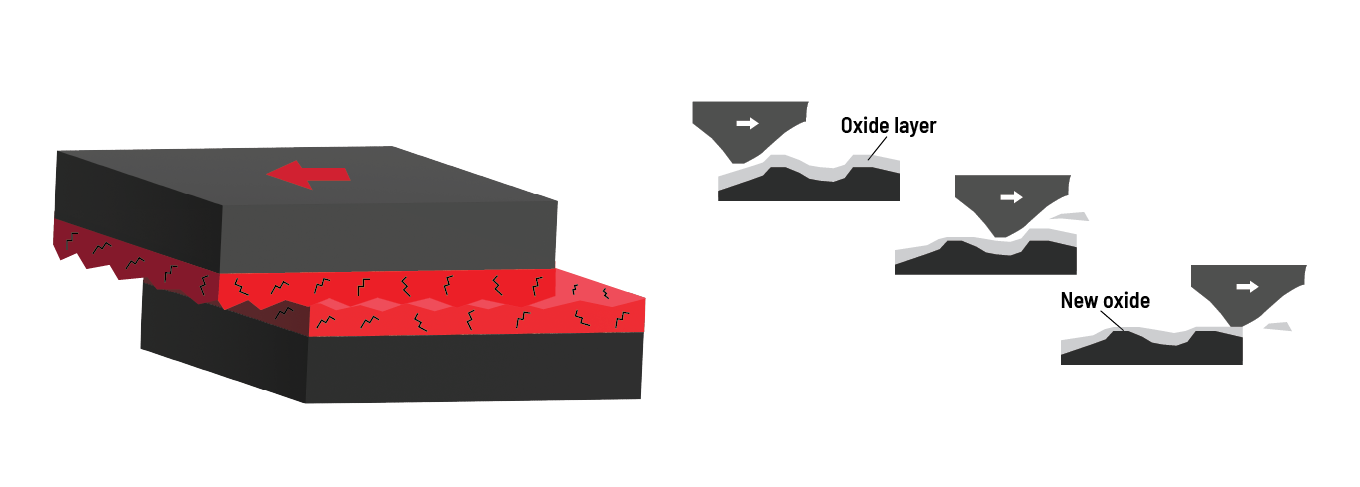

2.1.3. Tribochemical mechanism (Oxidation-corrosion)

This mechanism occurs due to chemical reactions on surfaces that slide against each other in the presence of reactive substances in water or gaseous environments. The products that result, which are normally brittle, are crushed and removed from the surfaces. This mechanism is especially active in marine environments or in some industrial environments where the humidity is high.

2.1.4. Surface fatigue mechanism

The mechanism takes place when the material is subjected to recurring mechanical and/or thermal stresses immediately contiguous to the surface. After a certain time, cracks will form above and just below the surface. These cracks will come together from time to time and will give rise to particles that eventually separate from the material.

In real situations, the named mechanisms rarely occur in isolated situations but in general occur as a mixture of several mechanisms in different proportions.

2.2. Factors affecting wear

Because many factors affect the intensity of wear, this phenomenon is a complex one. Therefore, it cannot be claimed that a material is wear resistant until the working conditions to which it will be exposed are known. A certain material may perform better than another in one situation, but the opposite may occur in another situation. The following factors can affect the wear behaviour for material.

- Mechanical properties: hardness, toughness and elasticity

- Chemical composition: affects the susceptibility to oxidation, and the hardenability

- Microstructure: phases, phase distribution, phase magnitude and grain size

- Atmosphere: could be “normal”, marine, industrial

- Environment: dry, humid or wet, temperature

- Geometry and position of the component subjected to wear

- Properties of the foreign matter: abrasive particles, stones, sand, metals, etc.

- Speed of the particles or bodies coming in contact.

3. Wear of Steel Plate

Wear of steel plate is mainly related to truck platforms, dumper bodies, excavator buckets, concrete mixers, mineral wagons and the like. In these applications, abrasion is the dominant wear mechanism and, therefore, this chapter deals with abrasive wear in more detail.

3.1. Abrasive Wear

As mentioned earlier, abrasive wear is defined as loss of material caused by hard bodies or particles which remove material from the surface of a softer material when the two bodies come into dynamic contact with one another. There are two main cases of abrasive wear: the first is sliding abrasive wear and the second is impact abrasive wear.

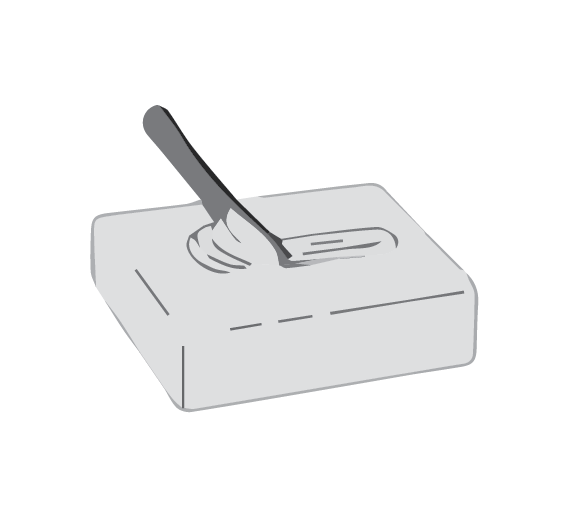

To give a simple picture of how sliding abrasive wear takes place, let us consider a packet of butter and a butter knife. The butter knife is the ‘hard object’ and the butter is the soft material. When the tip of the knife is pressed into the butter and is then pulled through it sideways, a portion of the butter will be removed, and a groove will remain in the surface of the butter. The weight of the original block of butter will decrease; that is, it wears. The same process occurs when sliding wear occurs on a steel plate, but the grooves and wear particles can hardly be seen with the naked eye.

Wear of steel plate occurs when the abrasive agent (hard irregularities or particles) cuts or gouges through the steel surface, which results in the removal of steel swarf. If the abrasive agent is a surface irregularity of a larger body, the process is known as two-body abrasion. If the abrasive agent consists of loose particles between the contact surfaces, the phenomenon is known as three-body abrasion. Under the conditions considered here, the abrasive agent consists of stones or minerals of various sizes, ore or sand.

In order to generate pure abrasive wear, the abrasive agent must be harder compared to the material being worn. Tests have shown that the Vickers hardness of the abrasive agent must be at least 1.2 times that of the abraded surface if significant abrasion is to take place.

Relatively soft particles (e.g., soft minerals or grain) may also cause wear of steel plate. However, in these cases, the wear mechanism is not pure abrasion but rather a mixture of abrasion, surface fatigue and corrosive wear.

3.2. Damaging mechanisms in sliding abrasive wear

Let’s go back to our previous butter and butter knife example. Depending on how the knife is held when it is drawn through the butter, varying amounts of butter will remain on the knife (more or less wear will occur). If the ‘angle of attack’ of the knife is greater than 90°, the amount of butter removed will be greater than if the angle were 90° or less. So as the angle decreases, the amount of butter collected will also decrease. If the angle is very small, the surface of the butter will be scratched, but no butter will stick to the knife.

As in the butter example, when a hard particle slides on the steel plate, it may cause varying amounts of damage to the surface, depending on the angle of attack.

a) The hard particle can plough into the steel without producing material removal, but it will result in a scratch and material shifting to the sides and the front.

b) The hard particle can cut through the material and push material ahead of it so that a ‘chip’ will form and break off after reaching a certain size.

c) Repetition of ploughing of the surface leads to surface fatigue, that is, the formation of microcracks above and slightly below the surface, which eventually results in detachment of wear particles.

d) If the steel is hard and brittle, ploughing can result in rapid formation of cracks and detachment of brittle wear particles.

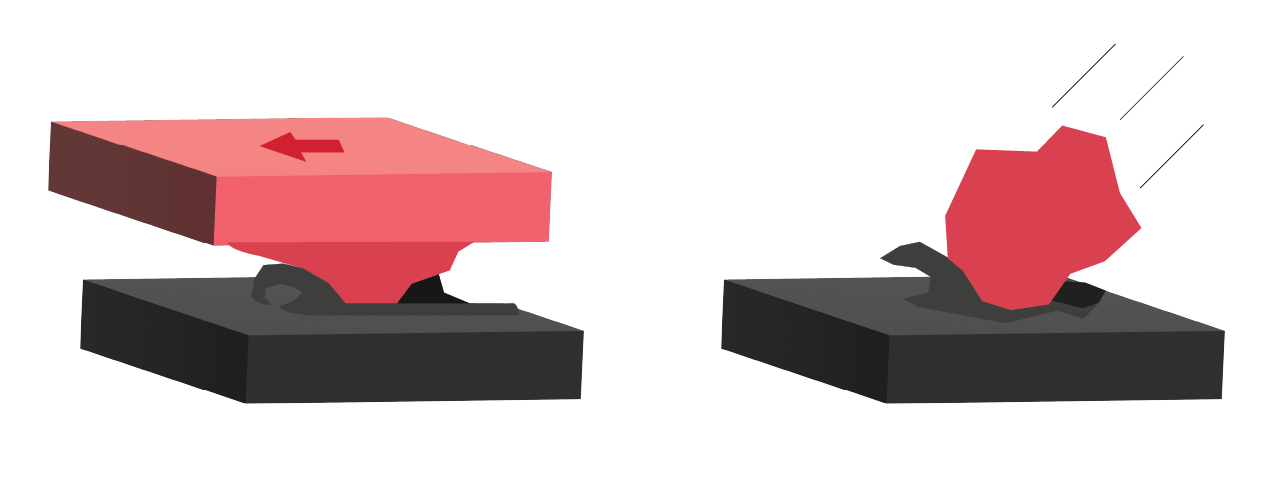

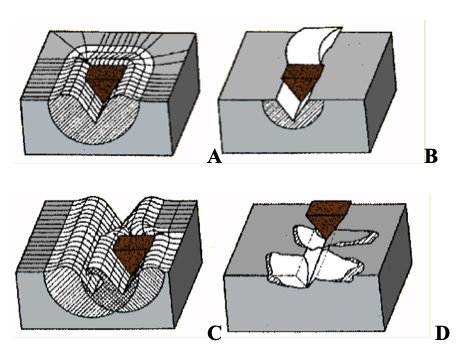

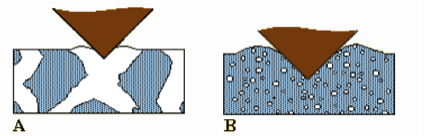

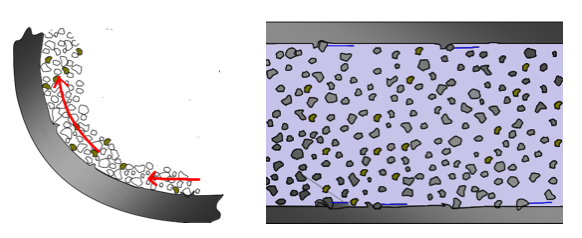

Out of these four mechanisms, the second is the most damaging. The following figure shows a schematic illustration of the concepts.

Main mechanisms in the abrasion of steel caused by hard particles.

A = micro-ploughing (low stress) and B = micro-cutting (high stress), C = surface fatigue, D = Brittle fracture.

When chip formation dominates, wear processes are referred to as ‘high-stress abrasion’, and processes where ploughing dominates are generally referred to as ‘low-stress abrasion’. The abrasion mechanisms are affected by angle of impingement of the abrasive particles and by the hardness ratio between the steel and the abrasive particles. The higher the hardness ratio, the deeper the groove in the steel plate and consequently the larger the wear intensity.

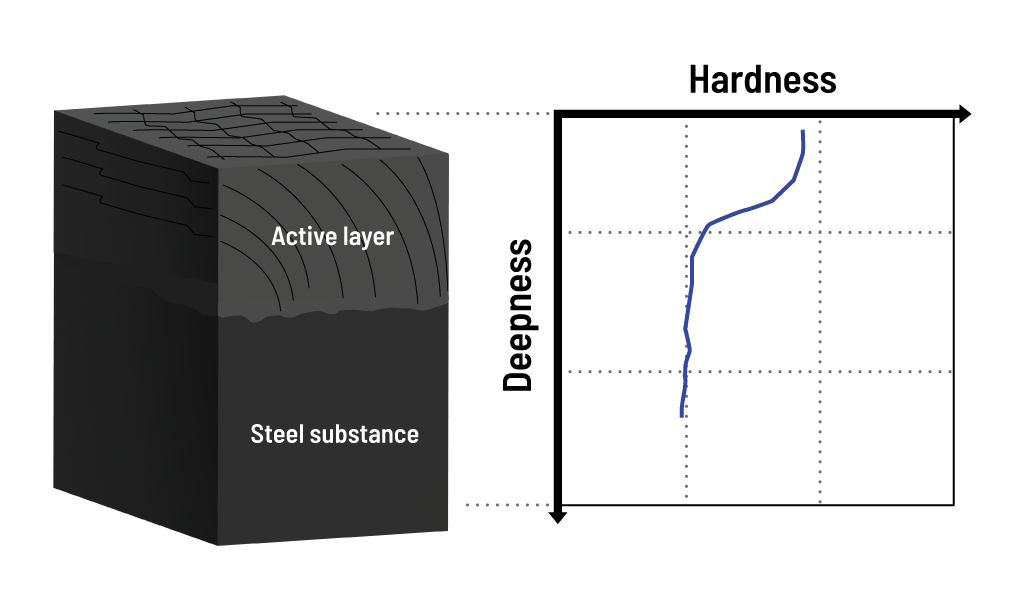

These four mechanisms, alone or in cooperation, contribute to the formation of a strongly deformed layer in the steel plate being worn, the properties of which may differ fundamentally from the properties of the underlying substrate. This deformed layer is called the ‘active layer’ and its wear properties, different than the substrate’s, determine the subsequent wear behaviour of the material.

Outline of a cross section of steel subjected to abrasive wear (left) and hardness profile (right).

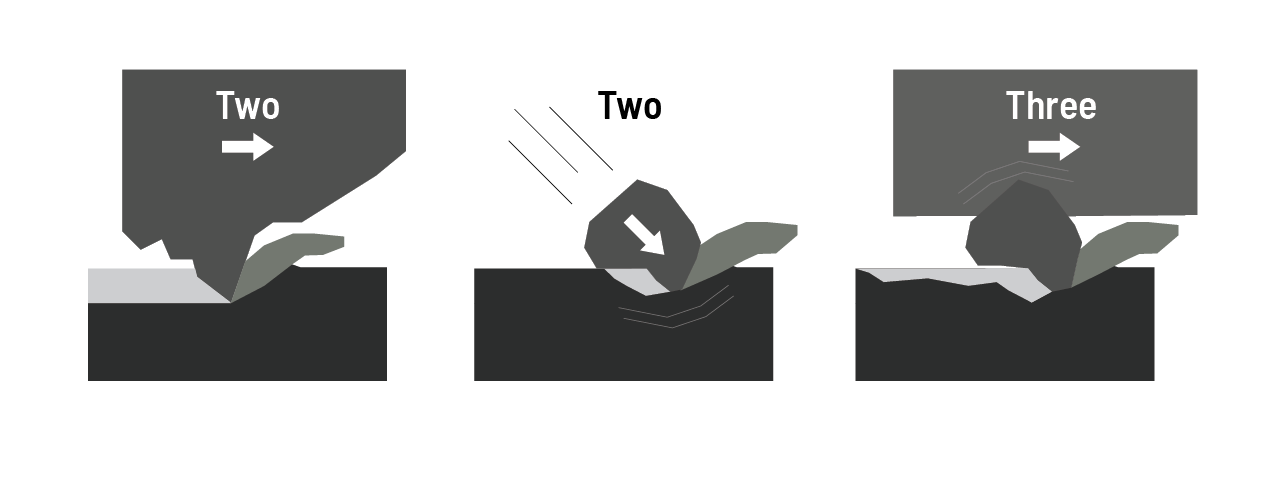

3.3. Damaging mechanisms in impact abrasive wear

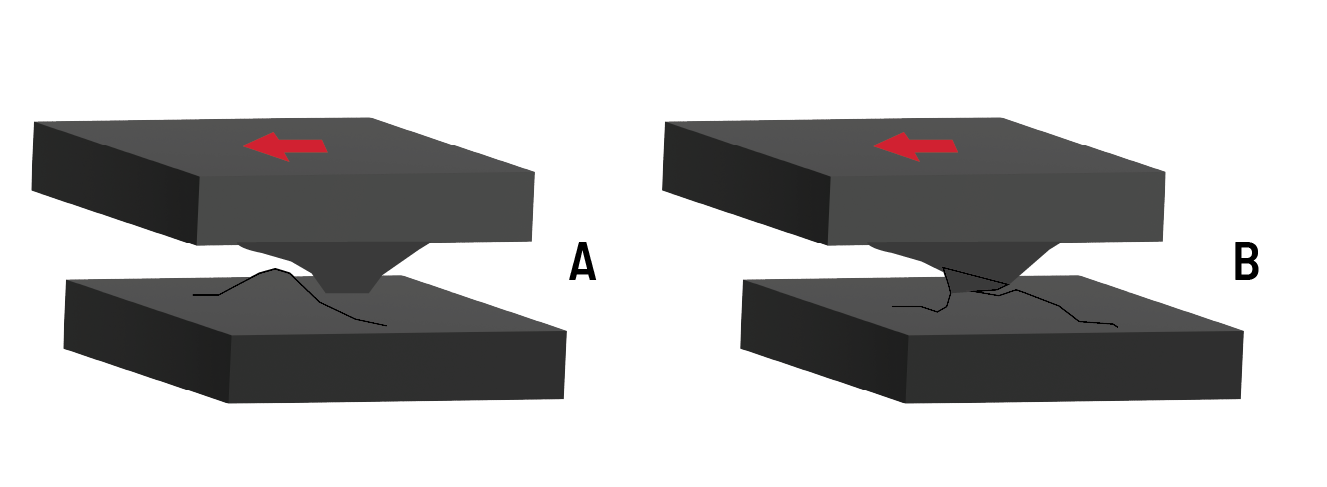

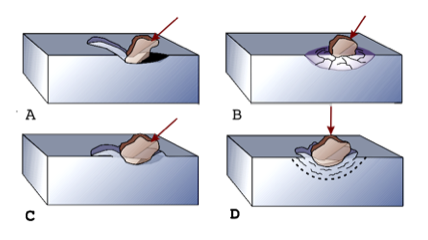

A hard particle hitting a surface (e.g., a steel plate) can cause different types of damage depending on various factors. The particle can: (A) cut a piece of steel in the form of a chip, (B) give rise to surface cracks if the steel is too brittle, (C) lead to ‘lips’ of steel around the impact site and leave a crater behind it, or (D) cause subsurface cracks if the impact is repeated several times in the same place.

Different damage mechanisms during impact wear. (A) chip formation, (B) cracking at the surface, (C) lip formation and (D) cracking below the surface. The first two mechanisms, chip formation and surface cracking, are the most harmful (high abrasion area).

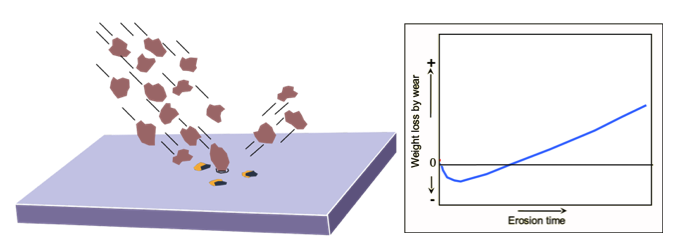

When wear is caused by small solid particles hitting the surface of steel plate at a certain angle instead of sliding across the surface, a mechanism called erosion takes place. This mechanism is characterised by the production of notches or detachment of wear particles. Moreover, repeated impact on the surface will damage it to such an extent that cracks will form, eventually leading to the expulsion of wear particles.

In a new plate, pieces of the impinging particles will leave some residue on the impacted surface after rebounding, which will cause an increase of the total mass of the plate (negative mass loss). This is exemplified by the diagram above that shows the results of an erosion test on a steel. After a period of time, the mass of the plate will start to decrease.

4. How to minimize abrasive wear of steel plate

4.1. Important steel plate properties

The properties of steel plate that most influence its resistance to abrasive wear are hardness and toughness. These properties, in turn, are affected by the composition and microstructure of the steel.

4.1.1. Hardness

A steel with a high hardness generally has better wear resistance than a softer steel. This statement is based on practical experience and, to some extent, also on laboratory research, which has led to the statement being regarded as a rule of thumb.

This ‘rule’, nevertheless, is valid only as long as the application and steel type remain broadly the same. Generalizations should be avoided, as there are cases where other properties or characteristics of the selected material may be more important than the hardness of the material.

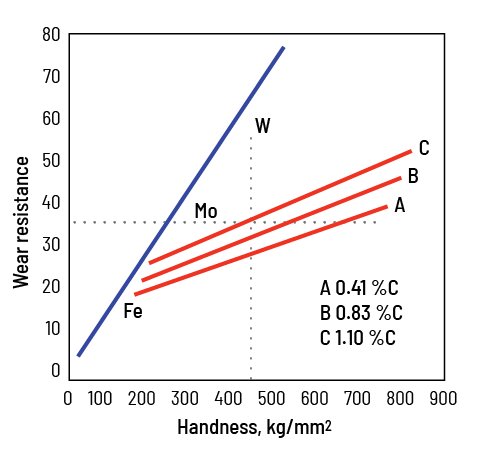

Below is a graph showing the wear resistance of various pure metals and three different steels as a function of hardness. Pure iron (Fe), molybdenum (Mo), and tungsten (W) in annealed state closely follow the hardness rule of thumb, whereas the curves for steels A, B and C have different slopes. At a hardness of about 450, for example, three steels and one pure metal (W) have the same hardness but different resistances to wear. Similarly, it can be seen in the same diagram that steels with comparable wear resistance have quite different hardness.

Relationship between wear resistance and hardness for a number of pure elements and carbon steels.

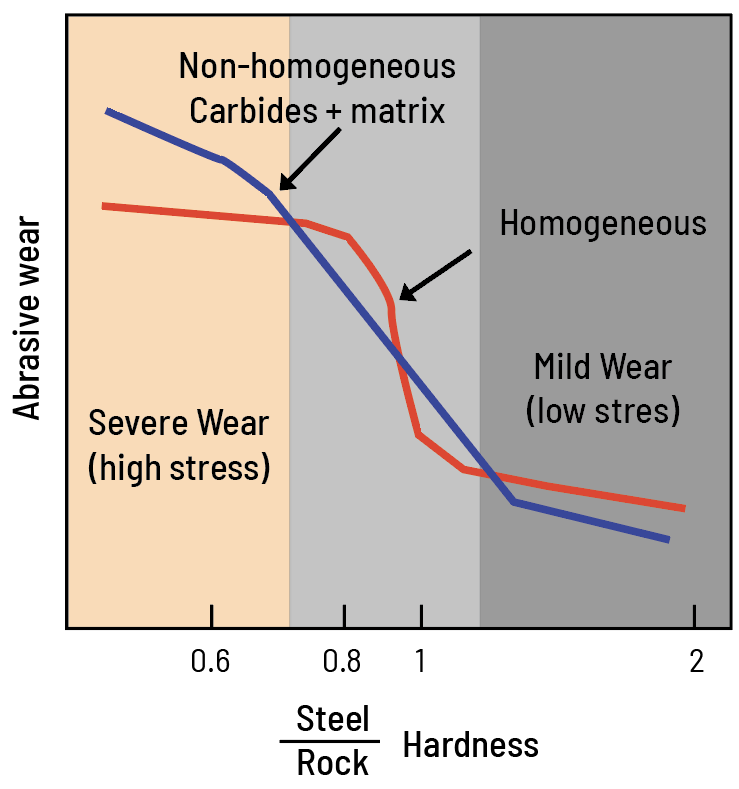

More important than hardness alone is the hardness ratio between the steel and the abrasive agent. Abrasive wear may be mild (low) or severe (high), depending on the ratio of hardness between the abrasive and abraded materials. Wear changes from low to high level when the hardness of the abrasive particle is equal to or greater than the hardness of the material being worn. Laboratory tests have shown that there is a critical steel/rock type hardness relationship of around 0.83 – 1.0, below which the chip formation mechanism dominates, as shown in the figure below.

Schematic illustration of the rock type/metal hardness relationship, with transition from low-stress to high-stress abrasion.

It must be taken into account that wear is a superficial phenomenon and takes place at the outermost layer of the steel plate. The hardness of this layer in relation to the hardness of the abrasive agent is therefore the factor that really needs to be taken into account when comparing the abrasive agent/steel hardness ratio. It is known, for example, that the active layer is highly deformed and has therefore undergone work hardening. It has also been found that a relatively soft material can trap a number of the abrasive particles in its ‘active’ surface layer during the abrading process, and can therefore be at least partially protected from further wear.

4.1.2. Toughness

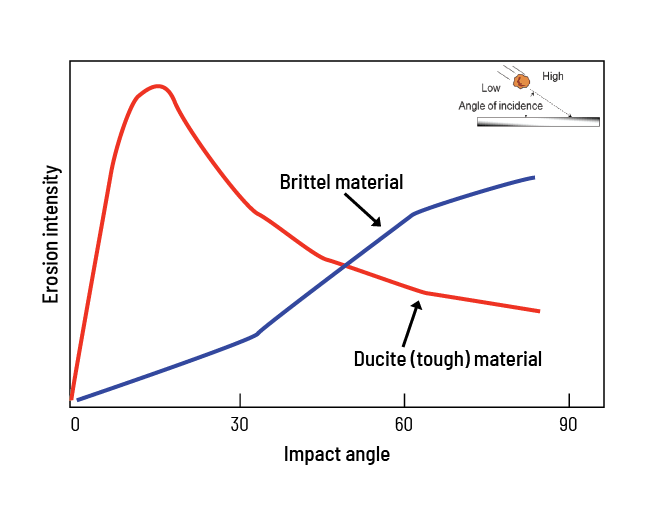

The importance of toughness to wear resistance arises in abrasive situations where the steel is subjected to impact by particles. A tough material performs better at high impact angles, while a hard (brittle) material will wear less at low angles. This relationship is shown by the graph below, in which the intensity of the erosion has been plotted as a function of the impact angle.

Erosion rate as a function of the impact angle on a ductile (tough) material and a brittle material.

4.1.3. Composition and microstructure

Abrasive wear resistance increases with increasing carbon content of the steel. This seems to be due to the fact that carbon acts in two ways that elevate wear resistance:

1) it forms carbides, and

2) it increases the hardness of the matrix.

Carbides, which are quite hard compounds, can promote or hinder steel wear, depending on their size and their cohesion to the matrix. An increase in the amount of such particles is normally favourable from the standpoint of wear resistance, although a more advantageous effect is obtained if the carbides are also relatively large.

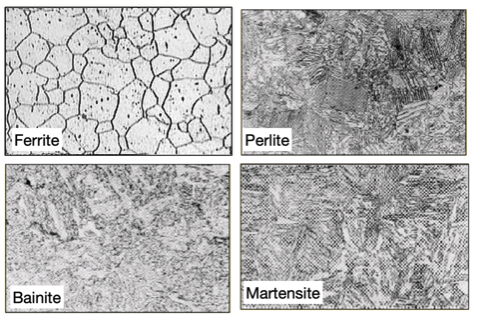

In carbon steels, the phases that can be present are mainly ferrite, pearlite, bainite, and martensite. The softest phase is ferrite and its wear resistance is lowest in purely abrasive wear, followed by pearlite, bainite and martensite, in that order. Martensite is normally the most abrasion resistant phase, although this rule is not invariable. As an example, bainitic structures containing a large proportion of residual austenite may have higher wear resistance than martensitic structures of equivalent hardness. The influence of phases on wear resistance also depends on their sizes, distribution, hardness, and cohesion with the matrix.

The following figure shows how a certain hard phase (white) can hinder abrasion in some cases (A), while playing a secondary role in others (B).

Influence of the size and morphology of the hard phase (white) in abrasive wear. (A) non-homogeneous structure, (B) homogeneous structure.

In wear situations, homogeneous and non-homogeneous structures behave differently. The latter (A) shows less intensity of wear in situations of mild wear than the homogeneous structure (B), see the previous figure, but the intensity of wear is greater in situations of severe wear.

Pearlitic steel has also been found to suffer relatively less wear than its bulk hardness would suggest. This appears to be due to the fact that the ordinary hardness test actually only measures the hardness of ferrite, whereas the hardness of pearlite colonies, which is much higher than that of ferrite, does not have a significant effect on the measured hardness. But in the process of wear, pearlite colonies resist material removal effectively.

A steel with a smaller grain size has greater resistance to wear. This is due to the fact that the greater amount of corresponding grain border efficiently hinders the deformation of the steel, that is, it increases its hardness. On the other hand, defects such as cracks, pores, inclusions (oxides, silicates, aluminates, and sulphides) and other stress-rising factors can have a negative effect on wear resistance.

4.2. Testing for wear

The most appropriate way to test the wear resistance of a steel plate, or any other material, is in real applications. However, such ‘field tests’ are expensive and time-consuming and therefore used sparingly. On the other hand, many accelerated laboratory test methods have been developed as alternatives to field tests, and these try to simulate real conditions. But the results of laboratory tests must be interpreted with caution and it must always be kept in mind that such tests represent significant simplifications compared to real conditions.

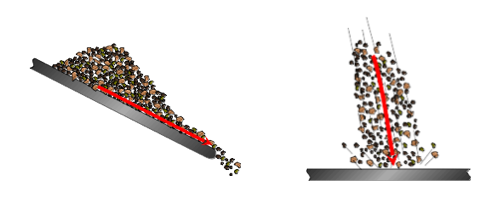

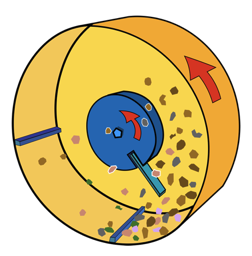

4.2.1. Paddle wheel machine

This machine is designed for testing abrasive impact wear resistance. It consists of a cylindrical drum that rotates around a horizontal axis during the test. A round disk mounted on a separate parallel shaft is located inside the drum and rotates at a higher speed than the drum. The test piece is secured to the disc so that it protrudes in the form of a ‘paddle’ and as the disc rotates, the paddle strikes against small stones that are scattered by the movement of the drum and serve as an abrasive material. The following figure is a schematic representation of the machine. The experiments are performed in a dry environment. The test pieces are machined to the following dimensions: 25 x 75 x 3 mm.

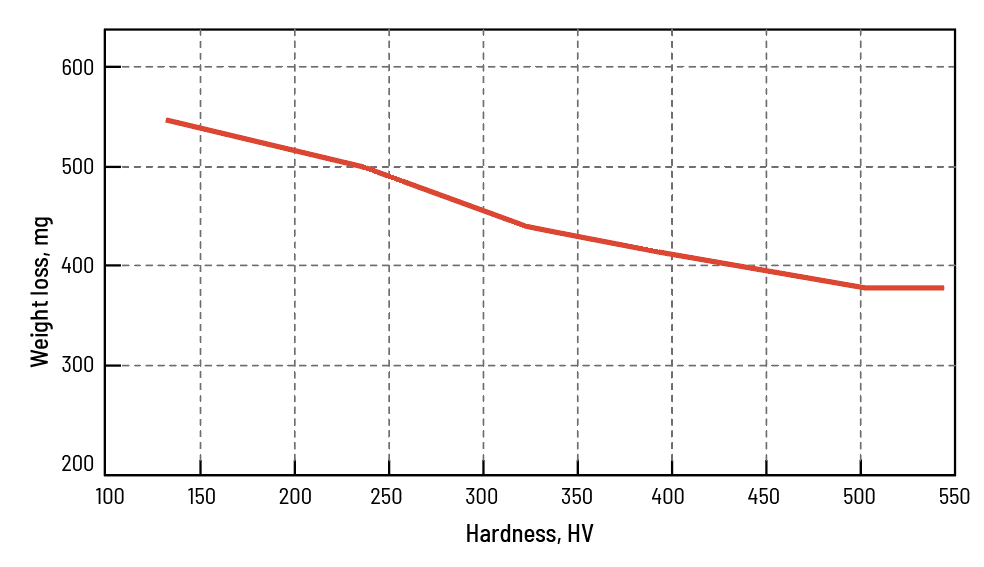

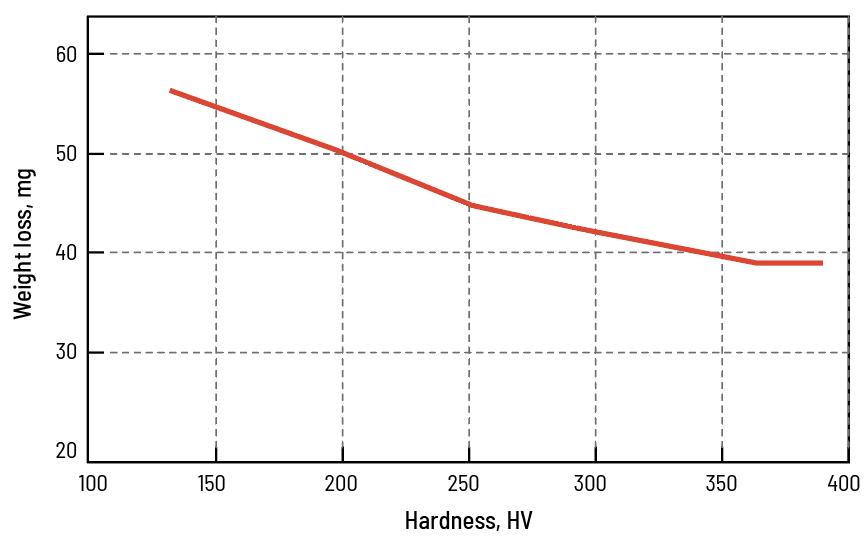

The average results of tests with steels of different hardness are shown graphically below as weight loss versus hardness of the steels.

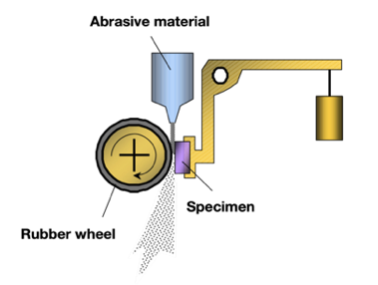

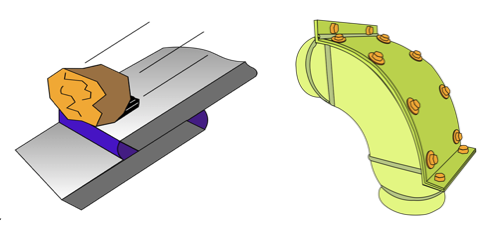

4.2.2. Rubber wheel machine

It is a widely used machine for testing three-body abrasive wear. The machine is standardized in many countries (ASTM G65). The sample is a right-angled block that is pressed against a rubber wheel. Abrasive material, a special sand, is dropped into the contact area between the rotating wheel and the sample. Wear is measured as the weight loss of the sample after the test.

The sample is tested for 6000 revolutions at a load of 13.6 kg, using a 229 mm diameter rubber wheel and dry sand.

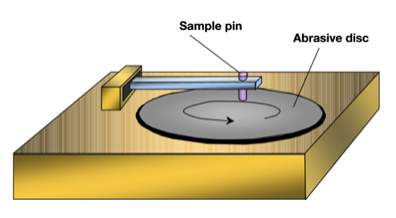

4.2.3. The pin-on-disc machine

This machine is suitable for testing resistance against sliding abrasive wear. The method is based on the gramophone principle, but the record disc is replaced by a sandpaper disc and the needle by the test piece. A constant load is applied to the test piece, which moves radially so that it is always in contact with untouched sandpaper. The test piece is a cylindrically shaped pin measuring approximately 3 mm in diameter and 25 mm in length.

Wear is measured as pin weight loss by weighing the pin before and after the test. By testing several steels of different hardness, a wear curve is obtained, exemplified by the following curve.

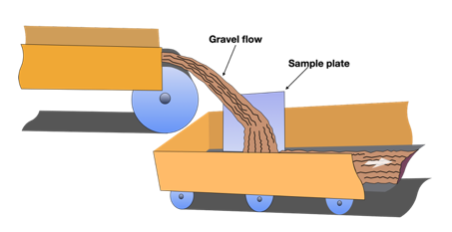

4.2.4. Field test

As mentioned earlier, the best way to evaluate the wear resistance of a steel plate in a given application is to use it under real conditions for a given time and compare its performance with that of the previously used material. This will give you a qualitative estimate of its wear resistance and hopefully an idea of whether it’s worth using in the future. This procedure is, as you can imagine, tedious, expensive, time-consuming and quite imprecise.

An alternative to field testing that comes closest to a reliable result is to subject relatively small pieces of the candidate steel plate to conditions as close as possible to the actual application and evaluate the results quantitatively. However, this method is not as easy and inexpensive as a laboratory test and requires careful design, preparation and performance. On the other hand, it will give you a reliable figure to use in your technical and economic evaluation.

As an example of the latest alternative tests mentioned, we can cite a test carried out with some grades of steel plate in a stone crusher in an asphalt factory. Steel plates with area dimensions of 500×500 mm were exposed to abrasion by a flow of gravel from a conveyor belt (see sketch). Each test lasted about two weeks and the plates were exposed to about 10,000 tons of gravel. The wear was calculated by the volume loss of the sample plate.

4.3. Design to counteract abrasive wear

4.3.1. Dimensions

The replacement of a common steel with another that’s resistant to wear would allow its thickness to be reduced, preserving the same useful life of the component. However, the general design rule says that you should not reduce the thickness of the plate to a value less than that required for strength reasons (stress, stiffness, impact stress, fatigue, etc.).

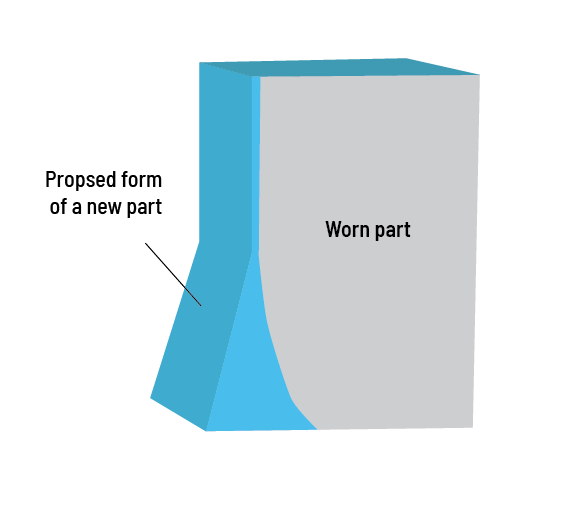

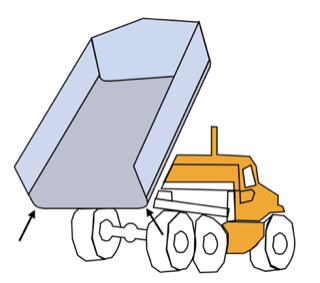

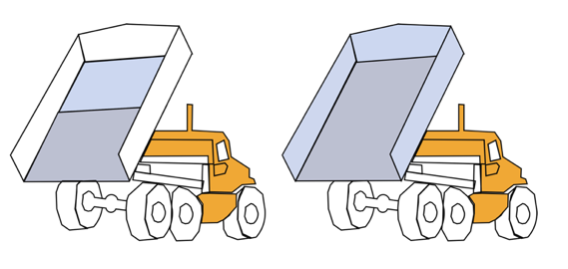

It is advisable to make the material thicker in areas where the wear is heaviest (see figure below).

4.3.2. Form

The shape of the component is important when it comes to designing against abrasive wear and the abrasive material slides over the surface of the component. Changes in the direction of movement of the abrasive material will cause higher stresses in the material being worn, resulting in increased wear. Therefore, it is important to take design precautions in circular shapes such as pipes, cyclones, and others. Pipe joints must not be radially misaligned. The flatness of the steel plate is also a requirement to consider. It is advisable to reinforce the pipe elbows with a material that is more resistant to wear than that of the straight areas.

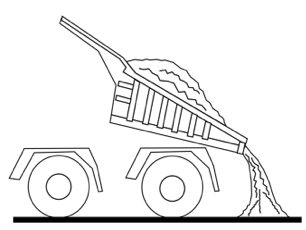

In the case of the Dumpers, it has been found that a rounded shape of the corner formed between the lateral sides and the bottom is convenient from the wear point of view.

4.3.3. Joining

The best way to join sheet plate parts is by welding. Good weldability is an important characteristic of steel plate. The filler metal must be chosen to meet the actual strength requirements. Generally, a filler metal intended for lower grade steels will be found to be sufficient. Make sure, however, that the welds are protected against wear, as illustrated in the figure. If welds are going to be subject to wear, use a hard welding electrode for the top bead.

In some cases, bolted joints can be a good alternative to secure steel parts that need to be replaced frequently and quickly.

4.3.4. Combination of different steel plate grades

Truck open-box bed bottoms subject to abrasive wear due to transportation of sand, gravel, or small stones wear differently at the front than at the rear part. In this case, it is advisable to combine different qualities of steel plate. The cost of welding will be less that the cost of changing the whole bottom prematurely. Even the lateral and front sides of the open-box bed normally wear less than the bottom, which should be taken into account.

4.4. Steel Plate Selection

4.4.1. General

In general, there are two situations in which a decision must be made regarding material selection: when it comes to material for a new application and when considering replacing the current material with a better one.

In the case of a new application, it is best to contact potential material suppliers. In their contacts with clients, providers have accumulated experience that they are often willing to share with other clients. In addition, when necessary, the supplier is also able to consult experts.

When considering material upgrades, don’t automatically select a harder steel. Only if the harder steel is a variant of the same type of steel will it get a longer service life. The best advice is to look at previous tests and operating results. Therefore, operating results from previous plants (actual initial sheet thickness, component loading, operating time, resources, material hardness, sheet thickness reduction) should always be considered.

Take into consideration the properties of the abrasive material and the environment to which the steel plate will be exposed. The harder the abrasive material, the greater the justification for selecting a steel plate of greater resistance to abrasive wear. When it comes to abrasive wear, the abrasive agent is usually minerals or stones of different sizes and hardness. In order to avoid an ‘overrated’ steel, find out or estimate the hardness of the rock.

If it is not possible to make tests prior to the use of a particular steel plate, the hardness rule can be applied, but use a healthy dose of common sense. In abrasive wear, a hard steel will perform better if stress is parallel to the surface or in a small angle of incidence. A tough steel is better at more perpendicular stress angles.

When large amounts of steel are required, it may be profitable to make an optimal selection and in that case, it is advisable to test different degrees of steel. For this reason, it is important to find a provider that is willing to cooperate and help the client perform tests or suggest where tests can be performed.

It is often desirable that the chosen steel plate also has other properties, such as a good bendability and weldability, as well as good wear resistance. A material that has a good combination of these properties can also offer new and better design solutions. Harder variants of quenched and tempered steels require special care in welding and, in certain cases, may need to be preheated.

In many cases, it is also worth combining steel plate of different thicknesses and qualities in the same component in which the intensity of wear varies from one point to another. For example, a tipper may need a plate that is thicker at the bottom and thinner at the sides and front. A harder quenched and tempered steel can be combined with a less expensive one.

It is always convenient to think in terms of general economics. It may be more cost effective to choose a wear-resistant steel plate from the start, rather than using plain carbon steel. Costs associated with downtime, repair labour, and stocking spare parts to replace worn parts can be combined to ensure the more expensive material will pay for itself in the long run.

4.4.2. Atmosphere and the environment

The atmosphere (dry, wet) and the environment play a large role in the rate of wear. In a corrosive environment (marine environment, garbage collection and treatment), corrosion and wear combine and cause wear to increase by an amount greater than either mechanism alone would cause. If the corrosion is significant, it will be necessary to have an additional corrosion margin in the thickness of the plate used.

A basic environment, for example in a lime quarry, increases the risk of stress corrosion cracking. In such cases, it is advisable to use a wear-resistant steel that is also resistant to stress corrosion cracking. In some cases, it may be necessary to compromise on wear resistance and choose a material that is resistant to stress corrosion cracking.

5. Application examples

TRUCK FLATBED

In wagon-bridges assigned to transport sand, gravel, and small and midsized stones, SWEBOR’s abrasion resistant AR-steel plate can be used with advantage. Wagon-bridges for refuse collection vehicles are an ideal application.

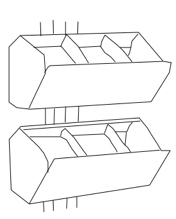

STEERING EXCHANGERS IN CONVEYOR BELTS

The sidewalls of mineral ore or stone conveyor belts, usually made of steel, are subject to intense abrasive wear. In these places, SWEBOR’s abrasion resistant AR-steel plate has a considerable advantage over ordinary carbon steel.

CEMENT MIXERS

In cement mixers there are a lot of components that are subjected to hitting and gliding gauging against abrasive particles of different sizes. The thickness range of SWEBOR’s abrasion resistant AR-steel plates means many possibilities for interesting technical solutions.

DUMPERS

Mineral dumpers are subjected to severe abrasion wear by large, medium and small rocks of minerals of different kinds and hardness. SWEBOR’s abrasion resistant AR-steel plate is a wise selection.

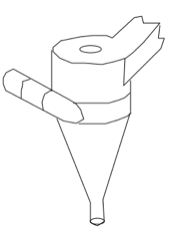

CYCLONES

Cyclones are used to separate particles of different sizes and specific weight, for instance in the mining industry. The particles rotate at high speed and expose the steel walls to strong abrasive wear. SWEBOR’s abrasion resistant AR-steel plate, with its wear resistance and bendability, is an appropriate material choice

TRANSPORT BOXES

In the cement industry and similar industries, transport boxes are very often used to elevate sand, gravel or cement. Wear-through abrasion limits the life of the boxes. Manufacturing transport boxes with SWEBOR’s AR-steels helps the wear problem. Besides, manufacturing is made simpler with the excellent bendability and weldability of SWEBOR’s abrasion resistant AR-steel plate.

SILOS

Silos are used with the building, cement, mining and agricultural industry. The lower conical part is particularly subject to abrasive wear. Repairing, if possible, is time consuming and expensive. Therefore, it is worth it to increase the lifetime of the silo by using a wear resistant steel such as SWEBOR’s abrasion resistant AR-steel plate.

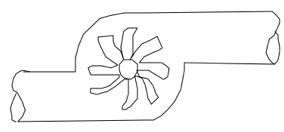

FANS

Fans for dust, especially in the mining and cement industry, are worn tremendous amounts by sharp and hard particles. With SWEBOR’s abrasion resistant AR-steel plate, the fans are easily manufactured and have a longer life.

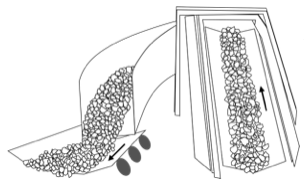

VENTILATION AND SLURRY TRANSPORTATION ELBOWS

In places where abrasive particles of different sizes (even powders) are extracted and transported in tubes, such as mines, quarries, and cement factories, there are elbow-shaped parts that require a material resistant to wear by abrasion. These places suffer so much abrasion that the plate has to be changed often, so solutions such as the one shown in the drawing are appropriate.

WAGONS FOR MINERAL ORE

In the mining industry, and sometimes in the building and agricultural industry, small wagons are used. These wagons are subjected to large loads and abrasive wear. SWEBOR’s abrasion resistant AR-steel plate is adequate as construction material from both the mechanical and the wear resistance point of view.

6. Abrasion resistant steel plate from Swebor

SWEBOR’s abrasion resistant AR-steel plate is both hard and tough, yet easily formable and weldable.

Wear plates from SWEBOR have a unique chemical composition designed for the best abrasion resistance. Combined with the optimum rolling, careful heat treatment and processing, SWEBOR’s abrasion resistant AR-steel plate possesses a unique combination of hardness, toughness and workability. Low carbon equivalent guarantee good weldability.

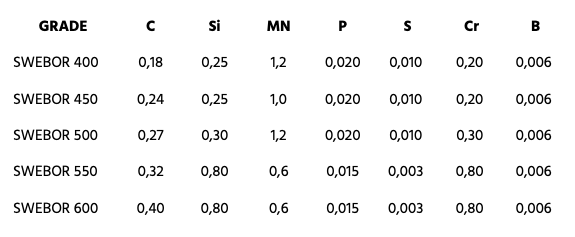

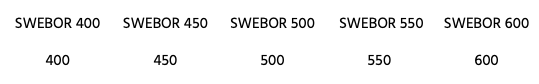

Grades: SWEBOR 400, SWEBOR 450, SWEBOR 500, SWEBOR 550 and SWEBOR 600.

APPLICATIONS

SWEBOR Wear plates™ are designed for use in construction, mining, and agricultural machinery and other equipment.

CHEMICAL COMPOSITION (typical values of ladle analysis in wt.%)

Other alloying elements may be added. For more info contact SWEBOR.

DELIVERY CONDITION

Quenched.

HBW HARDNESS (DIN EN ISO 6506-1)

Tolerance = +/-10%

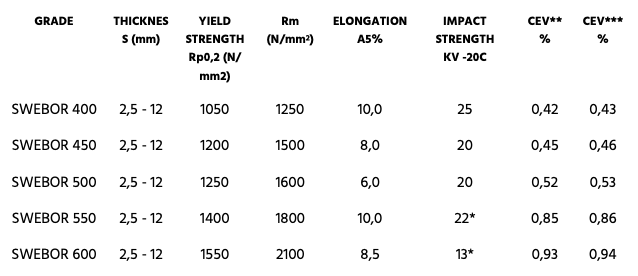

MECHANICAL PROPERTIES AND CARBON EQUIVALENT (TYPICAL VALUES)

*KV impact strength at -40C

**CEV according to IIW: CEV= C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

***CEV according to AWS: CEV= C+(Mn+Si)/6+(Cr+Mo+V)/5+(Ni+Cu)/15

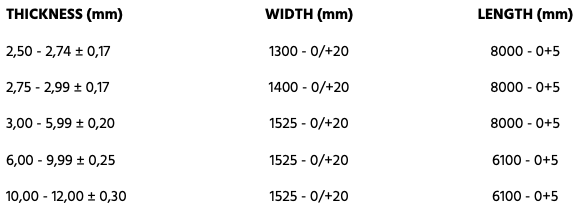

DIMENSION RANGE

CERTIFICATES – Can be delivered with analysis certificate and hardness certificate upon agreement.

WEIGHT – The weight can be calculated using a density of 8 g/cm3.

SURFACE TYPES – Heat-treated and brushed mill finish. VCI treatment can be obtained upon agreement.

FLATNESS – According to EN10051 material class C. For special flatness demand, please contact us.

WELDING – SWEBOR 400, 450 and 500 can be easily welded. Plates must be clean and dry. Commonly used filler metals for quenched steels are Esab 48.00 and OK Autrod 12.51. If high strength is required for filler metal, OK 75.75 or OK Autrod 13.10/13.12 is suitable. Equivalent filler metals from other suppliers can also be used. Always use low-hydrogen welding consumables.

For SWEBOR 550 and 600, we recommend MIG/MAG welding. For welding of SWEBOR 550 and 600, SWEBOR Stal recommends austenitic consumables (recommendation AWS307 – ER 307 – EN 1600: E 18 8 Mn R 12 – DIN 8556 : E 18 8 Mn R 26 – AWS A-5.4: E 307- 17 – EN ISO 3581-A: E 18 8 Mn R 12 – W.Nr.: 1.4370). Both grades shall be preheated to a temperature of not more than 100°C. Preheating is applied for hydrogen content control (expulsion of moisture).

Interpass temperature for SWEBOR 550 and 600 should not exceed 150°C. Backstep welding principle should be used for proper interpass temperatures. Recommended gas mixture is 2 – 2,5%CO2 + Ar or 2 – 2,5 Ar + 1%02 + Ar.

WELDING HYGIENE

A good welding hygiene is to be considered: Pollutants such as water, oil, dust, paint and rust must be removed.

INFLUENCE OF ALLOYING ELEMENTS

For being hardened steel, SWEBOR steel has a relatively low alloying content, with a good weldability as a result. Generally, a higher alloying content requires higher preheating and a higher heat input.