Without great people we wouldn’t have great products!

Meet Greger. He’s one of the Process Operators at our steel factory in Jokkmokk. Greger has been part of the Swebor team for almost 3 years. His key responsibilities include hardening the steel, as well as doing checks and maintenance on equipment and machinery.

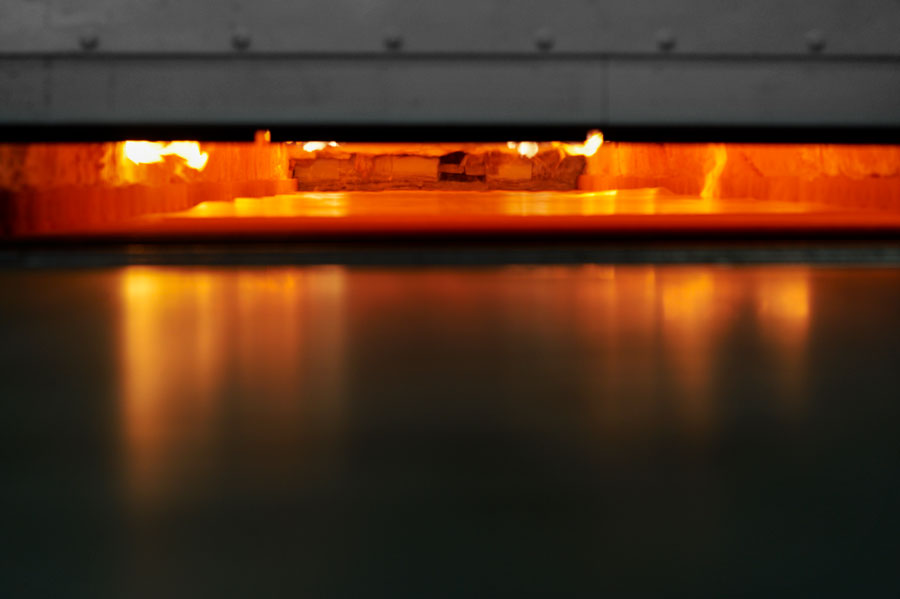

The process of hardening the steel consists of heating it up, and then taking it through a rapid cooling process called quenching. This technique involves using water to cool the steel down, so it is almost at room temperature. The sudden change in temperature makes the steel harder.

“Judging the correct temperature can be challenging,” Greger says.

“It means having a craftsman’s eye.”

Photo: Greger – Process Operator

A second heat treatment, known as tempering, is applied to achieve the ultimate hardness. The heating and quenching process makes the steel durable, and able to withstand a long life in a tough environment.

“All steel grades are different so various heat treatments have to be applied, and water pressure adjustments have to be made when developing each of the products,” Greger says.

“The hardening time varies a lot between different grades and products. Good planning is key – with good planning we can streamline the process.”

Hardening is a crucial part of the process and needs to be done right in order to achieve high quality steel products that last.

Steel grades like the Swebor Armor™ 600 are the most challenging to harden. However, years of experience and teamwork enables us to produce one of the most advanced ballistic performance properties on the market.

As a result, our team makes a product backed by hardness, high strength and weldability, which we can be proud of.

“There are always new things to learn when it comes to hardening steel – there is no manual for this kind of job,” Greger says.

“At Swebor, we try out different techniques and learn from one another.”

Swebor is a company based on quality and trust, and our skilled team is the driving force behind our success. Together, we are able to supply premium steel products worldwide and deliver on our promises.